Helix AG180folded

My audio system

|

Until now, my angular spiral had a tendency to be insufficient of bass output for a low Qts driver such as Fostex FE103E. I couldn't solve this problem for a long time. Recently, someone informed me that a folded spiral with front opening was effective for producing a plenty of deep bass. Now I have designed and built my own folded spiral for FE103E as described below. 15 mm MDF was used for the all parts of the speaker. Shellac was applied on the MDF directly without coloring. A small quantity of dumping material was placed on the wall behind the driver for easing a stimulus higher frequency. |

|

The result was satisfactory at first glance, but measurements indicated angular spiral was superior to folded spiral. The building was a bit tedious, and doubtful if it is worth to try. My first trial of folded spiral was to build a pair with twice as much fins. Its frequency response was worse than above-mentioned one with fewer fins. The big plunge in frequency response between 200 to 300 Hz was unrelated to the number of fins. The speaker box was sturdy and free of vibration because the all six outer walls were reinforced with fins and center plates. | |

|

16 fins All the fins had the same configulations. Angle 19 degree Length 122 mm Width 75 mm Thickness 15 mm The edges were rounded for smooth sound passage. |

|

Side plates and center plates with different length. The center plate with shorter length by 50 mm provided the sound passage for passing through upper to lower spiral. Edges of the center plates have grooves for cable. |

| Center plates and fins were glued on side plates. |

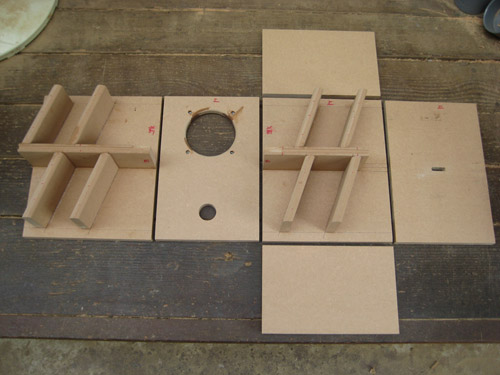

| The all parts |

| trial assembly 1 |

| trial assembly 2 |

| trial assembly 3 |

| trial assembly 4 |

|

completed assembly Prior to the shellac application, the surface of the box constructed by MDF was treated with an aqueous bond for woodwork. An aqueous bond was rubbed on all over the surface of the box with a wet cloth, dried, and polished with a thunder. The procedure was repeated twice. Thus, the surface of the box was hardened and ready for shellac application. |

| Angular Spiral | Folded Spiral |

|---|---|

AG180BS |

AG180folded |

|

|

| measured with FE103E listening position stereo,2m,center |

| mouth (opening) output mono center (border of the mouth) |

| listening position stereo,2m,center |

| mouth (opening) output mono center (border of the mouth) |

|

Vertical axis has an arbitrary linear scale and is proportional to the impedance of the driver. Resolution 5.383Hz |